How to Choose the Right Applicator

Before investing in an automatic applicator for self-adhesive labels, it is a good idea to make sure that it meets the requirements of the application you want to perform. Let's see what the primary deciding factors are when selecting the model that can meet your specific needs

APPLICATION CONDITIONS

Primary considerations to be made before choosing the most suitable applicator include:

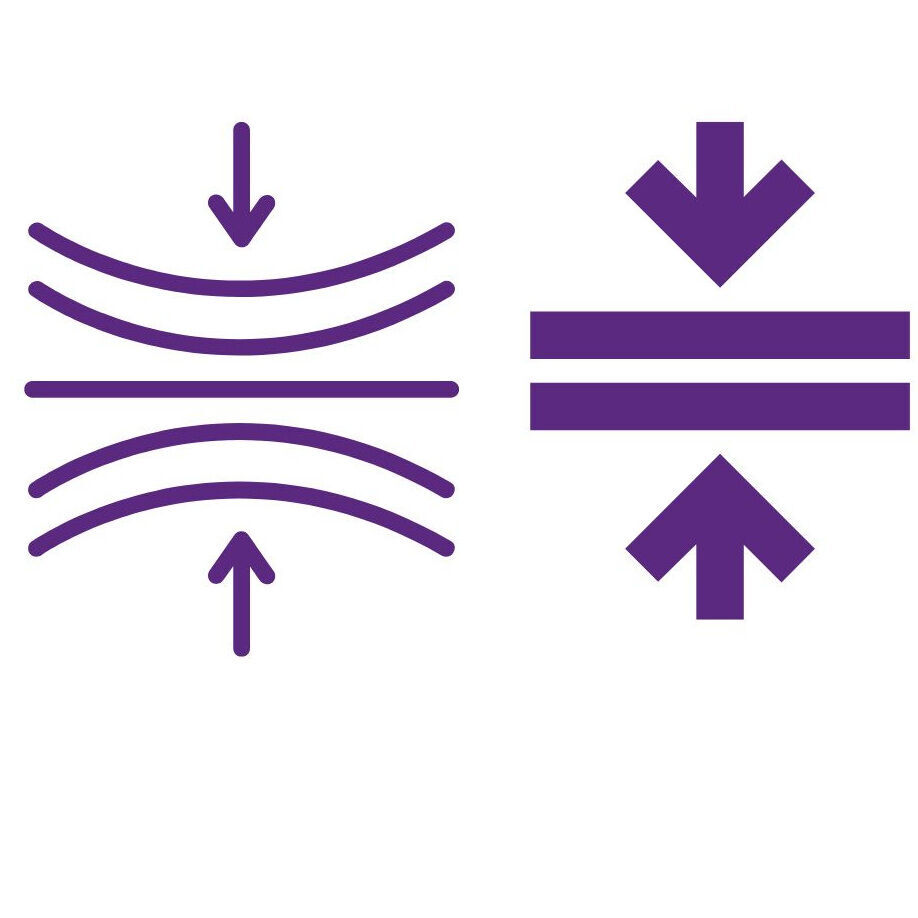

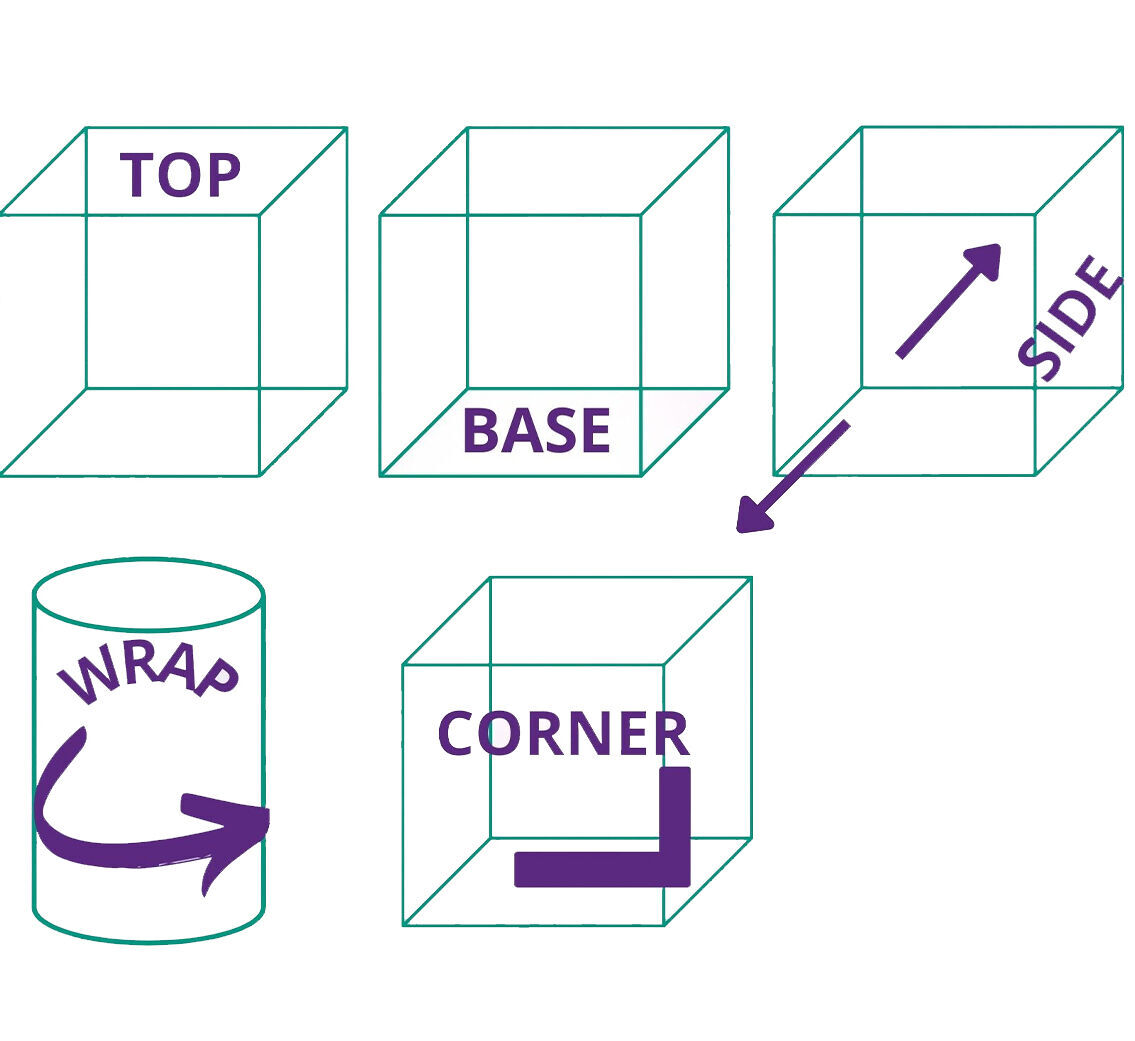

- Surface of the product to be labeled: the applicator must take into account the shape of the surface of the product to be labeled (flat, concave, convex, uneven? Clean or contaminated?).

- Is the material smooth or does it have unevenness? In other words, what should be labeled? A bottle, box, jar with a cylindrical, conical, or irregular shape?

1.jpg)

ARCA label applicators operate at speeds ranging from 20 to 120 m/min. (With variable speed an encoder must be used).

A label applied to a cosmetic or drug requires a higher level of accuracy for placement than a shipping label applied to a package.